Any and all problems solved, design needs met, repeat installations optimized. Too busy to get to it – outsource to us.

FIT-FOR-PURPOSE SOLUTIONS

W&W Energy Services deliver best-in-class engineering and design services to ensure our clients’ greenfield developments and brownfield modification projects are designed well and executed flawlessly.

Our 30+ years of experience and track record of success in the Permian means we understand the challenges of constructability and operability in this unique environment. We do everything from small scope single order engineering through to the innovative end-to-end EPC and EPCm project solutions.

Our experienced engineers and designers offer simple and practical advice. Our focus is on using our knowledge to optimize designs and improve safety, efficiency, and production while reducing total job and project costs.

We manage projects from initial design and engineering, through procurement and into construction – driving time and cost savings for our clients. These combined engineering and in-field services reduce the number of interfaces on any job to guarantee a successful outcome.

ADDITIONAL SERVICES

ENHANCED SAFETY

- Designed for safest construction

- Phased for simultaneous operations

- Set-up for easy maintenance

ENHANCED PERFORMANCE

- Survey site and collaborative scope development

- We include construction and operations teams in the design process

- Right-first-time designs, specs and materials

- Enables pre-fabrication and packaging

- Improved quality control and change management

- Reduces total installed cost

TECHNICAL ADVANTAGES

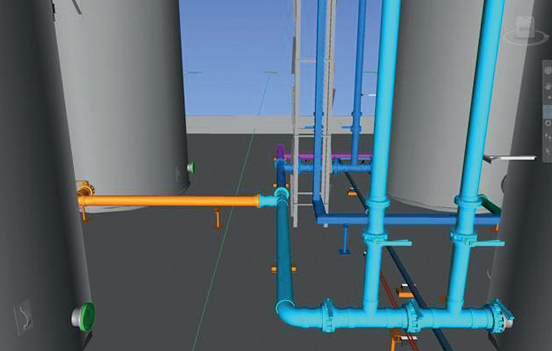

- Use of 3D modelling tools ensures all stakeholders are aligned from the outset

- Accelerated schedules – undertaking design optimization as projects are in flight

- Automated workflows and latest digital tools

DELIVERING VALUE THROUGH AN INTEGRATED APPROACH

Our engineering team is focused on improving full project execution, not accumulating billable hours. Our engineering discipline is part of our overall business solution, rather than a profit center in its own right.

Our fully integrated approach delivers value on both new facilities and modification of existing infrastructure for:

- Facilities

- Tank Batteries

- Salt Water Disposal

- Flowlines & Risers

- Well Pads

- Many other projects!

W&W LOCATIONS

CASE STUDY

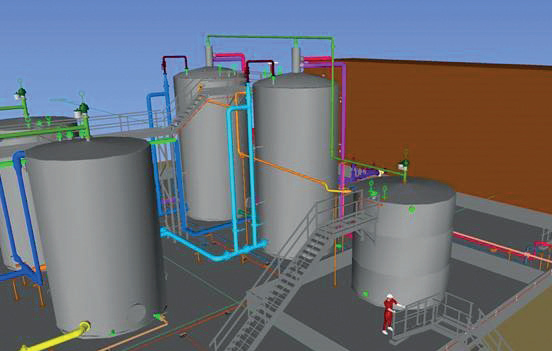

We collaborated with a client to leverage our mutual knowledge, experience, lessons learned and their great ideas. Results on a saltwater disposal facility:

- Removed 20% valves: 37 valves removed, 14 downsized, seven items de-rated

- 9% reduction in pipework: 221 ft of pipework removed

- Standardized designs, reducing future site-specific modifiable drawings to four

- Enabled pre-fabrication – improving safety, reducing logistics costs and mitigating weather exposure risk

- Developed a detailed scope of work for contractors to help the client manage other vendors

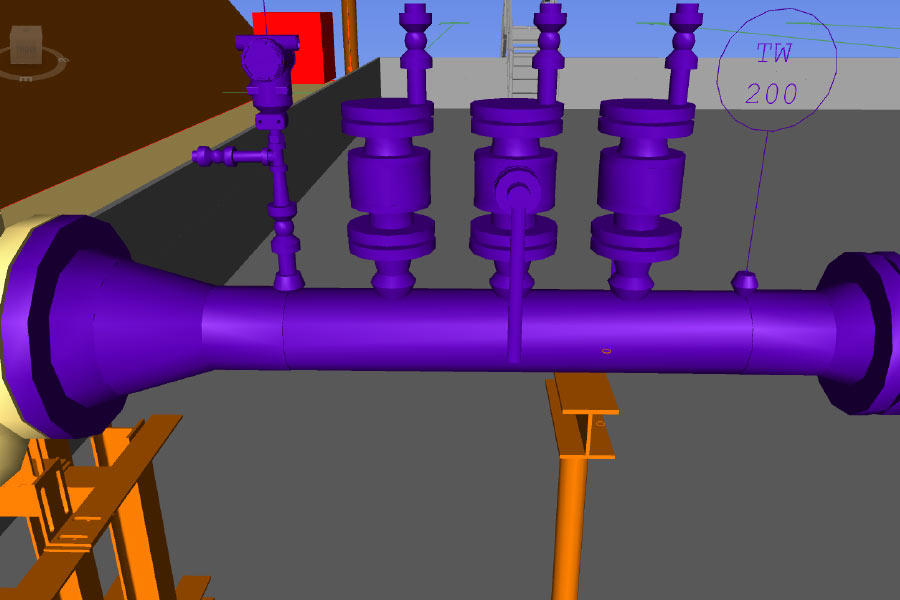

fig. 1 Fit for purpose engineering to enable pre-fab, optimize materials and improve repeatability

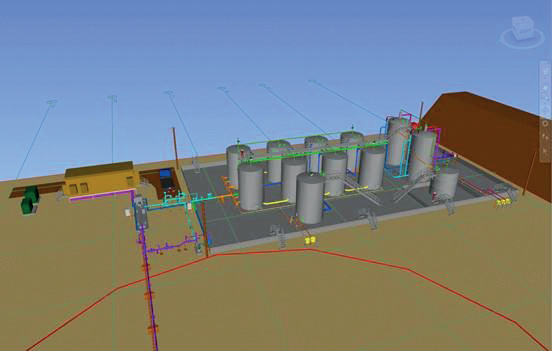

fig. 2 Optimized layout and improve model detail

fig. 3 Optimize piping design, reduce unnecessary components and improve operational flexibility

FOR MORE INFORMATION CONTACT:

Klay Cunningham

Engineering Manager

Tel: (432) 230-9393

Klay.Cunningham@petrofac.com